Applied AI: One Helping Hand To Address Environmental Sustainability and Emissions

Originally published by Ericsson

Can Artificial Intelligence (AI) really be used to help us fight climate change and build a more sustainable world? The simple answer is yes! The evolution of AI, with our ability to apply this technology and drive adoption, is enabling us to solve problems that previously seemed impossible. Here’s how Ericsson is working to lower one part of our supply chain’s carbon footprint by identifying and reducing CO2e emissions by using applied AI to optimize product transportation.

Why is essential?

Proactive management of topics relating to climate action and the environment is a core component of Ericsson’s sustainability strategy. makes up one of three main sustainability focus areas – with the other two being Responsible Business and Digital Inclusion (read more, here).With the growing threat of global warming, the negative impact of carbon emissions is an urgent worldwide concern. Pressure on businesses to accelerate climate action and limit global warming has never been more prevalent and the corporate world is making commitments for delivering its ambition to become Net Zero across its value chain. According to the US Environmental Protection Agency climate change report 2019, transportation alarmingly accounts for 29 percent of global greenhouse gas (GHG) emissions. Here at Ericsson, we take the need to decarbonize seriously. To address the threat head on, Ericsson has committed to reach Net Zero emissions in our value chain by 2040. Ericsson is already working towards a first major milestone to cut emissions by 50 percent in the supply chain and portfolio by 2030 and become Net Zero in our own activities at the same time. One of the key activities to address the reduction of supply chain emissions is Product Transportation.

In lieu of the above, and to meet our aggressive goal of reducing in CO2 equivalent emissions, the Group IT AI & Automation experts, along with Supply, have defined a to optimize product transportation – including monitoring, prediction, and reduction – with the ambition of applying AI to make the unimaginable possible.

How to measure and analyze CO2 equivalent emissions of transportation

But how could this strategic plan be implemented to actually make a difference in transport emissions and the areas of business beyond a company’s direct control? First, we needed the information to understand the full extent of supply chain emissions through measurable data and transparent reporting, referred to as the ‘monitoring’ phase.

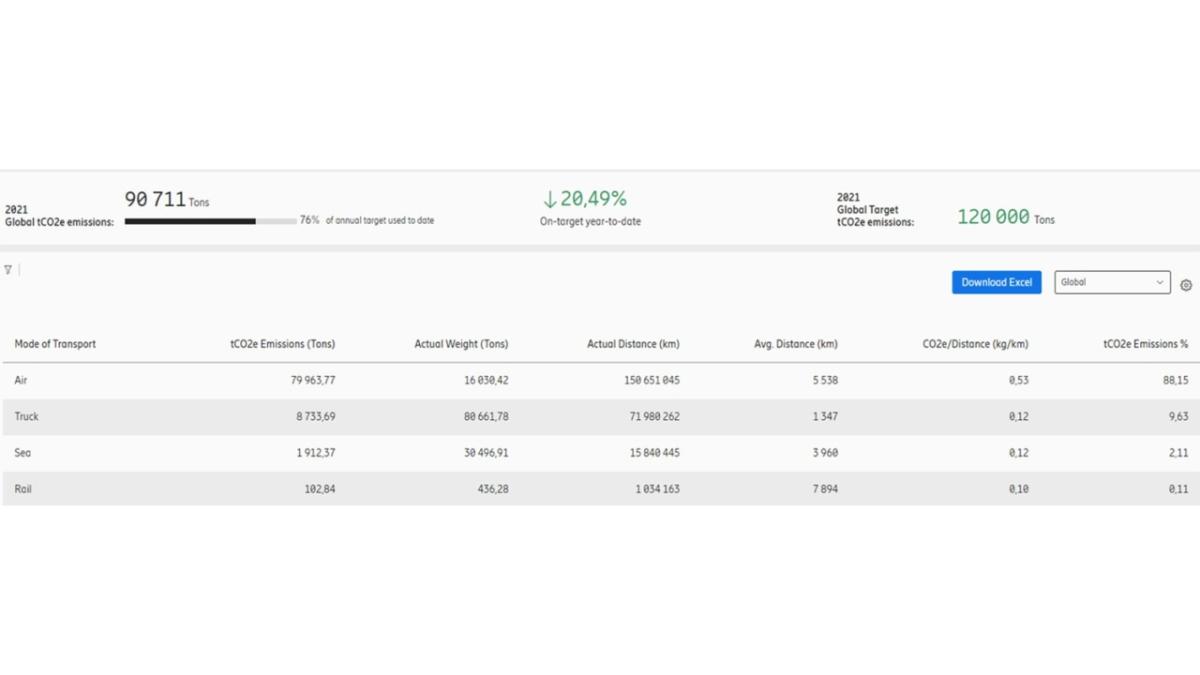

This phase helped map out the current CO2 equivalent emission scenario in the organization, including multiple complex product transport flows like customer supply chain, product supply chain, local transport and diverse processes. The primary challenge in developing such a solution was the lack of availability of data, related data from various sources and developing the precise logic to calculate the CO2 equivalent emission. With the help of various analytical techniques and fuel-based, distance-based, cost-based methodologies, we were able to calculate the emissions associated with transportation. After multiple trials and errors, the distance-based method was found to be the best suited approach for Ericsson Transport Management. We derived the CO2 equivalent emission by modelling frequent parameters like the volume of goods purchased, distance travelled, the standard emission factor for respective transport mode and/or type, and so on. The model was built generically enough to fit most similar transportation services. A simplified version of the calculations of the CO2 equivalents across various transport modes reads as follows:

Y=Σ (mass of goods purchased (tones or volume) × distance travelled in transport leg (km) × emission factor of transport mode or vehicle type (kg CO2e/ton or volume/km))

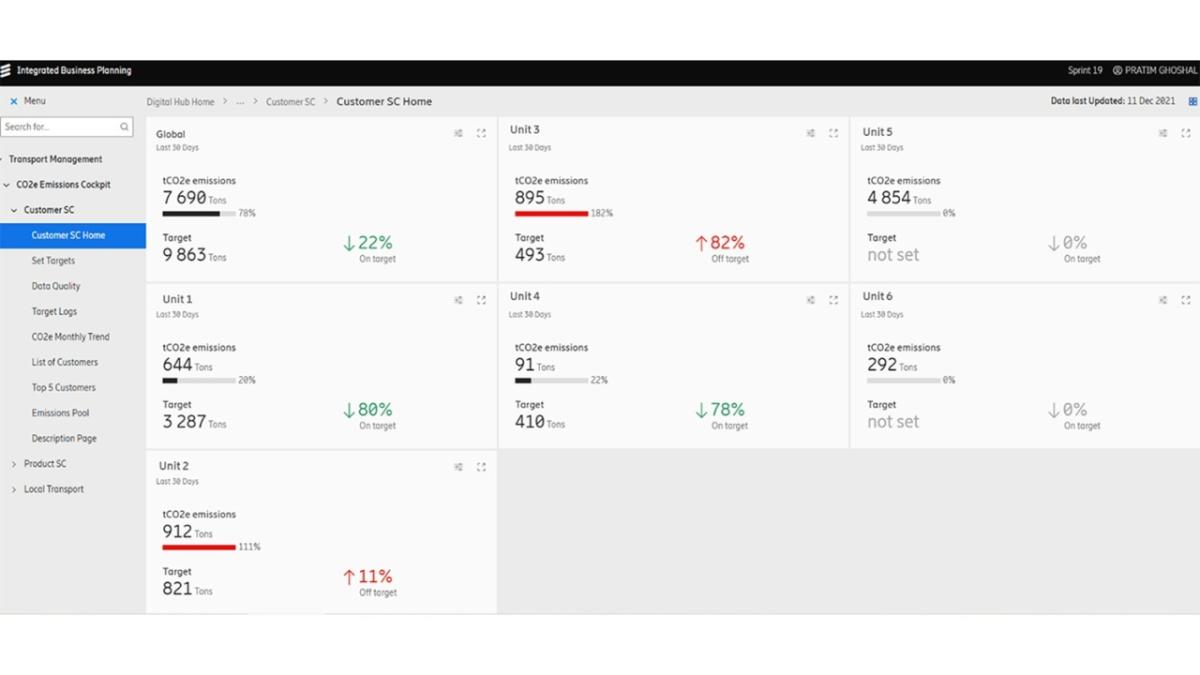

With the CO2e emission algorithm and LowCode web-based visualization dashboard allowing global users to interact at the same time, we were able to deploy a complete monitoring solution based on the data model, a reference snapshots of the dashboard (right).

Along with measuring and monitoring the C02e emissions across different transportation modes, we were able to improve data quality. By analyzing the collected data, the business could identify specific areas where the quality of the data was low and could drive initiatives with data stewards to improve the quality of the collected data and initiatives at the operational level to capture the right data. This iterative process of improving the data quality will gradually help the business drivers to take judicious decisions.

Transforming data into future insights: Prediction phase

With data and basic analysis in hand, the next logical step was to capture important patterns and trends to predict future business, noted as ‘Prediction’ phase.

Forecasting shipped volumes and weight for various transportation lanes was a complex process due to the high level of disaggregated freight flows. The uncertainty in transportation services, diverse processes and non-standardized procedures made it more challenging to attain optimal transportation resource utilization and distribution planning.

With the application of machine learning (ML) techniques such as regression, clustering, deep learning and so on, and by using historical and transactional data, we developed a more accurate long-term and short-term shipment weight forecast than what we obtained with manual predictions.

Applying such approaches not only reduces the need for manually generated forecasts, but also helps Logistic Service Providers (LSPs) to have better delivery precision leading to improved rates and hence reduced cost. The forecast will ensure the availability of transport capacity and reduce the lead time significantly.

Using a good forecast, the LSPs can identify the key drivers in shipment freights across regions and transport lanes along with the impact on the overall product transport chain.

The modeling part of the solution is comprised of multiple boosting algorithms having a wide range of hyperparameter tuning on features like learning rate, max_depth, n_estimators, subsample. Due to volatility and inconsistencies in the data, no single model could produce results, hence an ensemble of machine learning models was developed with different hyperparameters. The framework was designed such in a way that the best models (for tech savvy people, this was implemented through lowest WMAPE, Weighted Mean Absolute Percentage Error) would be picked up in a dynamic mode during runtime and would be utilized to forecast the related weight/volume.

Prediction to actions – Reduction phase

After measuring and analyzing the results of CO2e emissions and having good long and short-term forecast, it is now time to prepare plans and implement methods to reduce the CO2e emissions, also known as the ‘Reduction’ phase.

With the help of monitoring and forecasting, continuous admonitory processes can surely contribute towards iterative optimization of CO2e emission.

- Reducing and improving transport activities

- Fleet Optimization – Higher filling degree in trucks, reduce unnecessary air shipments, and updated fleet.

- Improved planning of packaging and transporting material, better supplier collaboration.

- Improving transport efficiency

- Avoid short lead time by using forecasting

- Use well-organized navigation

- Predictive analytics to prevent failure of vehicles and effectively use less energy (Predictive Maintenance)

In short, the logistics transport sector is one of the main consumers of fossil fuels, and is therefore a major contributor to the total greenhouse gas (GhG) emissions, accounting for of total GhG emissions, as per the US Environmental Protection Agency climate change report 2019. From our own operation, we have learnt that AI can be used to reduce the use of transport vehicles by optimizing the flow of vehicles, providing more efficient navigation, and facilitating shared transport.

Based on our insights on the potential of AI and the ongoing development in industry automation, this blog post has highlighted our three-phase strategic approach – Monitoring, Prediction, and Reduction.

Along with enhancing the visibility and transparency of CO2e emissions, as well as improving data quality, operational efficiency and customer satisfaction, transport volume forecasting is aiming to reduce both CO2e and operational expenditures.

We believe Environmental Sustainability challenges could be addressed through this three-phase approach, together with the strong domain knowledge. If used sensibly, we have no doubt that AI will accelerate our sustainability efforts.

AI is already shaping up to be the key to empowering governments, organizations, and individuals to make more conscious decisions and work towards creating a healthier planet. At Ericsson, we are working towards this cause and are proud to be able to demonstrate how applied AI can make a sustainable change.

The gravity of climate change together with artificial intelligence’s potential makes it too essential not to try, don’t you think?