Applying a Pattern of Excellence

From research to reality: Meet Neoterix ST

Imagine an innovation that reduces the accumulation of bacteria the moment germs hit a surface by 90–95 percent without the use of toxic chemicals that can lead to the development of resistant organisms. It may sound like something straight out of a science fiction novel, but it’s real—and Sappi paper helps make it possible.

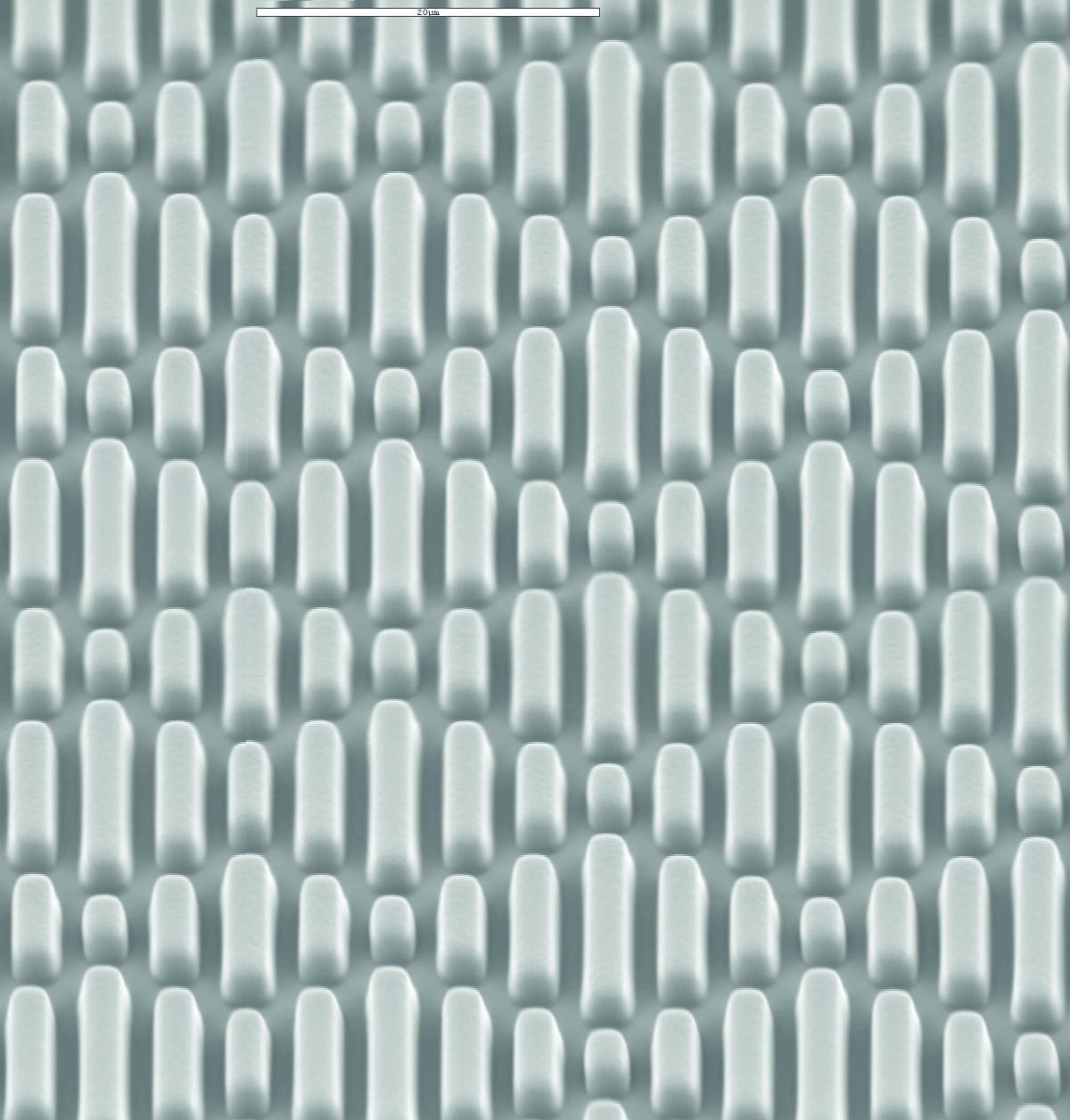

In 2002, while researching a seemingly unrelated problem, materials science engineering professor Dr. Anthony Brennan noticed that algae and barnacles don’t attach to sharks the way they do other marine life. After further investigation, he discovered a microscopic surface pattern on the dermal denticles of sharkskin that prevents microorganisms from latching on. He wondered if he could recreate this pattern in a way that would yield similar results outside of the ocean. That’s how Sharklet™ microtexture was born.

This truly innovative micropattern is the first of its kind, one that reduces bacterial contamination at the point of contact without the use of toxic chemicals. However, while the possible applications seemed endless, one issue still remained: how to apply the texture to various surfaces.

Always on the lookout for the next industry-changing innovation, Sappi’s Casting and Release business stepped in, licensing the microtexture to create Neoterix™ ST. This groundbreaking product acts as a mold to transfer the texture to the desired surface, making it simple to apply to things like furniture, paneling and wall coverings, and helping to drastically minimize the aggregation of bacteria in places where germs tend to accumulate, such as hospitals, hotels, schools and offices.

Neoterix™ ST may prove particularly important in locations where traditional antimicrobials are being banned. “A year and a half ago, a major health care organization on the West Coast banned a list of 14 different antimicrobial solutions from its hospitals in the pursuit of providing healthier environments for their patients,” stated Michael Greene, a Senior Marketing Manager for Sappi’s Casting and Release business. “They’re either going to rely on standard cleaning practices or will need to look at other technologies. Neoterix™ ST is a great option, because it has no chemical additives or toxins.”

Sappi doesn’t plan to stop with Neoterix™ ST. After much experimentation to find the right way to apply the pattern to their release papers, opportunities to commercialize other microscopic textures surfaced. One of these is a pattern that refracts light, breaking it up into individual colors to create a rainbow effect. This light-refracting microtexture launched as an aesthetic texture, and it’s one that shoe companies have already shown particular interest in adopting thanks to the superb brilliance of the light effects in a fabric they already know how to use.

Read more from Sappi North America's 2016 Sustainability Report here: http://bit.ly/SNA-2016SR