Takeaways From Panel Discussion at Sustainability Summit

I enjoyed hosting a panel discussion with my colleague Nasreen Chopra, who leads the Systems Engineering Center of Excellence for Applied’s Semiconductor Products Group, and Betty Jiang, head of U.S. ESG Research at Credit Suisse, as part of the Semicon West Sustainability Summit, within Applied CEO Gary Dickerson’s keynote session. I’d like to highlight three key takeaways from the panel.

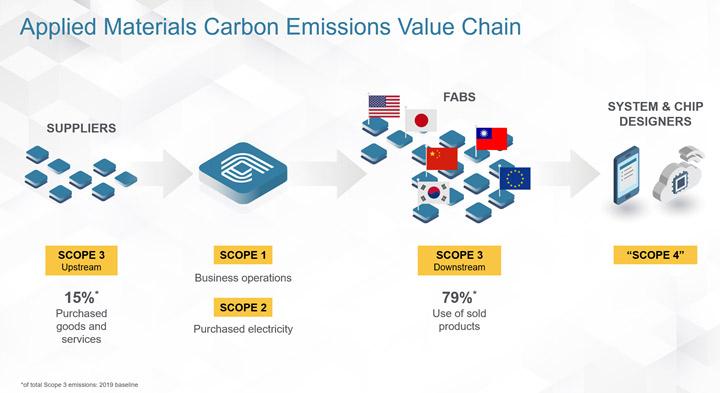

Takeaway 1: Scope 3 emissions are a large part of our carbon emissions value chain.

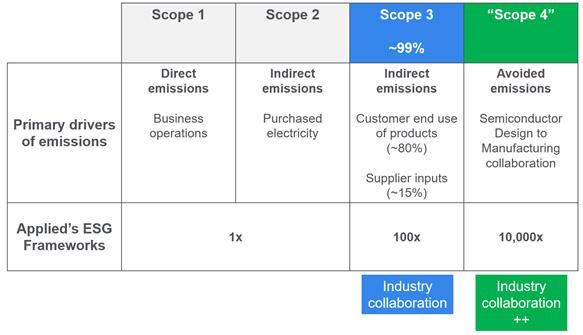

The Greenhouse Gas Protocol (GHG Protocol) offers companies different levels of commitments to advance their sustainability journey. For Applied, Scope 1 and Scope 2 cover emissions from the company’s direct operations and indirect emissions due to purchased electricity, respectively. Scope 3 represents 99% of Applied’s carbon emissions footprint for semiconductor products, of which nearly 80% is driven by the use of Applied’s products within semiconductor fabs to make chips. About 15% of Applied’s Scope 3 emissions for semiconductor products originate from supplier inputs. See chart 1 for Applied’s carbon emissions value chain.

System and chip designers determine what types of chips are needed to meet workload and application computing requirements. System and chip designers together with fab operators decide the manufacturing technology (aka “process node” or “technology node”) to be used for high-volume manufacturing of specific chips. They also decide which particular fabs will be used to make those chips. Depending on where a fab is located geographically, it may or may not have adequate access to clean energy for its operations. Carbon emissions due to fab operations represent the fab’s Scope 1 and Scope 2 footprint, and the portion attributable to Applied’s products within the fab drives Applied’s Scope 3 footprint.

Like the writers of the GHG Protocol intended, Scope 3 is designed to encourage a “full system” collaborative approach to lowering shared emissions. Ignoring Scope 3 would relinquish big opportunities to collectively transform the carbon footprint of the semiconductor industry.

Takeaway 2: The semiconductor industry needs to take a holistic approach to cut emissions.

Clearly, the entire value chain can reduce its carbon footprint by making smarter choices about chip architectures, manufacturing technology and fab geography through a collaborative approach. We think of emissions avoided through such an approach as Applied’s “Scope 4” emissions. To enable Scope 4 avoided emissions, the industry would need a priori access to data and analytics estimating potential carbon emissions resulting from design, technology and fab choices. Ideally, cross-industry collaboration would allow chip and system designers to iteratively optimize for value chain carbon emissions in addition to PPACt (power, performance, area, cost and time-to-market) considerations.

The concept of Scope 4 emissions would fit within Applied’s 10,000x strategy framework introduced in 2020 (see chart 2).

A recent Applied blog post provides transparency to how the company has calculated Scope 3 emissions for its semiconductor products and the holistic approach that has been taken. Looking at the details of the Scope 3 calculations, it only becomes more apparent that working across the semiconductor supply chain is critical for this industry to achieve its sustainability targets.

Takeaway 3: Now is the time to take action, while carbon remains mispriced.

Betty’s thesis is that higher carbon prices are needed to accelerate environmental sustainability progress, including innovation and investments in carbon reduction and removal, as well as clean energy generation and the electricity grid. If the semiconductor industry waits for more stringent government policy before taking meaningful actions on environmental sustainability, carbon prices would likely shoot higher by multiples of what they are today. Given the complexity of industry-wide collaboration needed to reduce value chain emissions, the industry would be better served by starting now, while carbon prices remain lower than they should be to meet science-based targets.

I look forward to sharing more of our thinking and progress as Applied advances its sustainability journey.